In manufacturing and heavy industries, overhead crane components are critical for lifting and transporting heavy loads. However, the efficiency and safety of these cranes depend heavily on the quality and functionality of their components. From the hoisting motor to the crane end beam, each part plays a crucial role in ensuring smooth and secure operations. Understanding these overhead crane components can help businesses make informed decisions, improve operational efficiency, and reduce maintenance costs.

Core Components for Crane Operation and Safety

- Hoisting Motor

The hoisting motor is one of the most vital components in any crane system. It controls the vertical movement of the load by providing the necessary power to the hoist mechanism. By choosing a high-performance motor, businesses can reduce energy consumption while ensuring reliable and continuous operation. Additionally, a well-maintained hoisting motor extends the overall lifespan of the crane.

- Hook Assembly & C Hook

The hook assembly is responsible for securely holding the load during lifting. In applications where additional support is needed, the C hook is often used to lift cylindrical or heavy items. Both of these components must be durable and able to withstand high stress, especially in demanding industrial environments. By investing in high-quality hook assemblies and C hooks, companies ensure that loads are lifted safely, minimizing the risk of accidents.

- Hydraulic Brake

The hydraulic brake is crucial for controlling the crane’s stopping ability. It prevents accidents by ensuring the crane halts smoothly and securely. Hydraulic brakes are particularly important for precise stopping, especially when dealing with heavy loads. They offer better control compared to mechanical brakes, reducing wear and tear and improving safety.

Drive and Operational Components

- Drive Wheel

The drive wheel allows the crane to move horizontally along the tracks. It ensures smooth movement of the crane along its rails, directly affecting operational efficiency. A well-maintained drive wheel prevents unnecessary friction, reducing energy consumption and wear on other components. Businesses should ensure that the drive wheel is compatible with the load capacity and operational environment.

- Coupling

The coupling connects the motor to the crane’s moving parts, transmitting power from the motor to the wheels and other components. By selecting a high-quality coupling, the system’s overall efficiency improves. This part helps maintain the synchronized movement of the crane, ensuring smooth operations and reducing the likelihood of mechanical failure.

Electrical and Control Systems

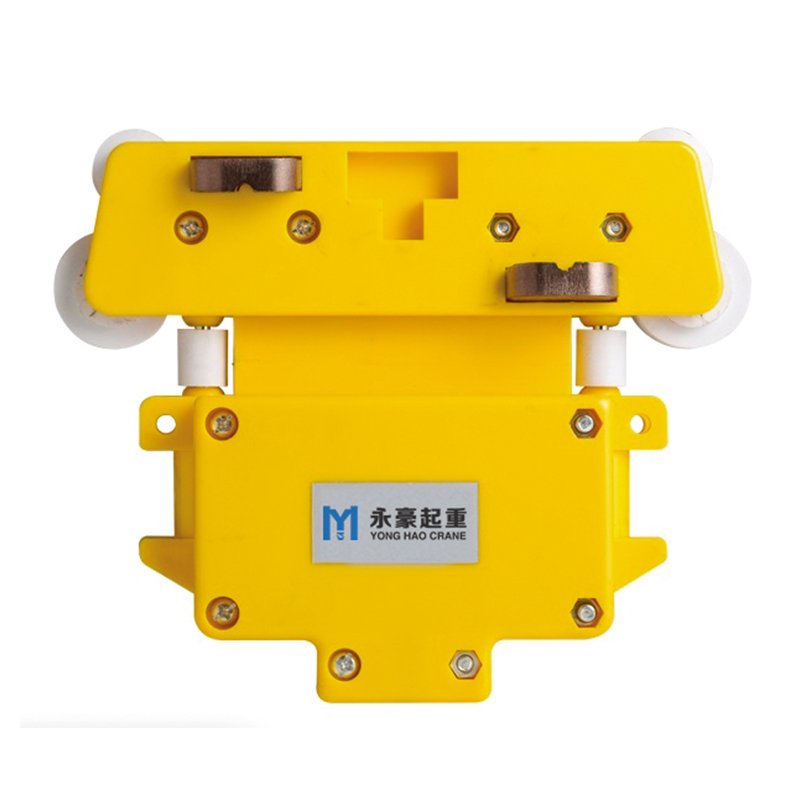

- DHG Collector & Non-Seaming Collector

The DHG collector and non-seaming collector are part of the crane’s electrical system, responsible for transferring electrical power to the crane. These components ensure that the crane receives a consistent and stable supply of electricity. The non-seaming collector, in particular, is essential for maintaining uninterrupted power flow during crane operations. Proper selection and maintenance of these components help improve operational reliability and minimize downtime.

- Remote Control

Using remote control systems adds flexibility to crane operations, allowing operators to control the crane from a safe distance. This feature reduces the risk of operator injury and enhances precision during lifting and positioning tasks. Remote controls are especially useful in environments where the crane needs to operate in hazardous conditions, as they allow for safer operation without exposing workers to danger.

Crane Framework and Structural Components

- Crane End Beam

The crane end beam is an essential structural component of the crane, providing support and stability. It is responsible for connecting the crane to its overhead rails and plays a significant role in load distribution. Choosing a durable crane end beam ensures that the crane remains stable under heavy loads, preventing structural failure and maintaining safety.

How to Choose the Right Crane Components

Selecting the right overhead crane components is crucial for ensuring efficiency and safety. Here are a few considerations:

- Load Capacity

The load capacity of the components, including the hoist motor, hook assembly, and crane end beam, must align with the weight of the items being lifted. Overloading any component can lead to system failure or accidents.

- Operating Environment

Different work environments, such as high temperatures or corrosive settings, may require specialized components. Ensure that the materials used in the crane’s parts can withstand environmental factors to prolong the system’s lifespan.

- Maintenance Requirements

Regular maintenance is essential to keep all components functioning smoothly. Establishing a maintenance schedule for key parts like the hoisting motor, drive wheels, and hydraulic brakes helps prevent costly repairs and reduces downtime.

Related article: Common Overhead Crane Maintenance Myths and the Right Ways to Maintain Your Crane

Conclusion

The right selection of overhead crane components is essential for optimizing crane performance, ensuring safety, and increasing operational efficiency. Key parts such as the hoisting motor, hook assembly, hydraulic brake, and crane end beam all play crucial roles in lifting heavy loads securely. By investing in high-quality components and maintaining them properly, businesses can enhance the overall reliability of their cranes.

At Yonghao Crane Co., Ltd., we offer a wide range of top-quality crane components, including CAB, C Hook, Coupling, DHG Collector, and more. Our components are designed to meet the highest safety standards and provide exceptional durability. Contact yonghaoqizhong@163.com today to learn how our crane parts can optimize your operations.