In modern industrial production, efficiently and safely lifting heavy loads is a core challenge. Whether in manufacturing, construction, or energy sectors, the Hoist Lift is an indispensable piece of equipment.

Understanding a hoist lift’s structure and principles helps avoid wrong selections, reduce maintenance costs, and significantly improve operational efficiency.

1. What Is a Hoist Lift? — From Definition to Component Structure

Many customers confuse Hoist Lift, Crane Hoist, and generic Lifting Hoists. In simple terms, a Hoist Lift is a device designed to raise or lower heavy loads vertically using mechanical or electrical power. It is the core unit among all hoisting equipment.

Definition

A hoist lift uses a chain or a wire rope to connect to the load and achieves vertical movement through drums, gear systems, or motor drive. Unlike passenger elevators, hoist lifts are specifically engineered for industrial load lifting—not for carrying people.

Typical Components

- Drive system (Motor / Manual drive) — supplies lifting power.

- Transmission (Gearbox) — provides torque reduction and smooth lifting.

- Load-bearing element (Wire rope / Chain) — directly connects to the load.

- Brake system (Disc brake) — secures the load when stopped.

- Control system (Control panel / Remote) — for manual or remote operation.

- Protection devices (Limit switch, Overload protector) — prevent overload and misuse.

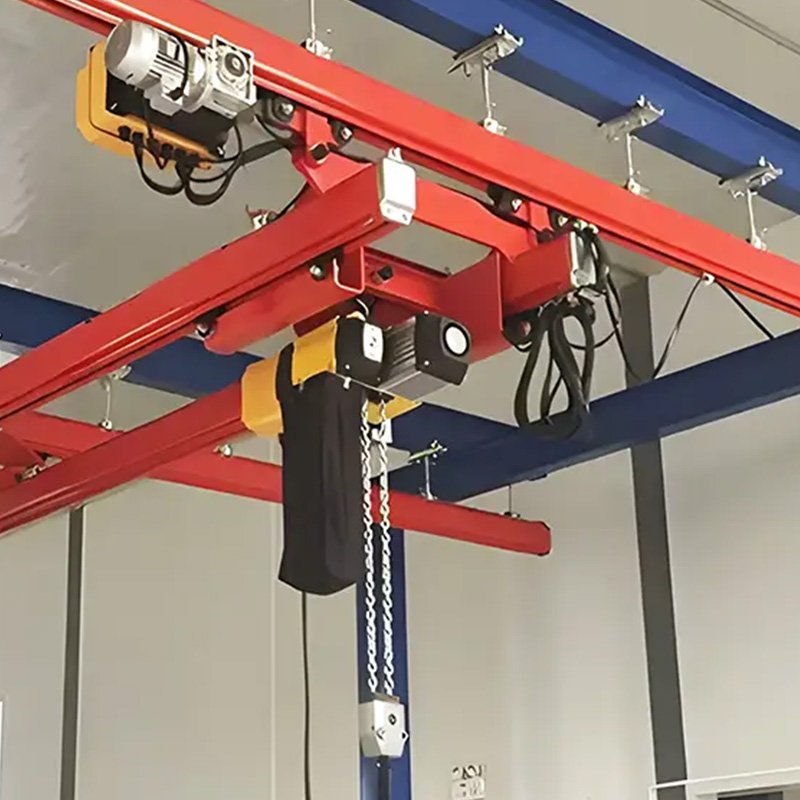

Relationship with Crane Hoist Systems

A hoist lift frequently serves as the central component of a Crane Hoist System. When mounted on an overhead, gantry, or jib crane, it performs vertical lifting while the crane provides horizontal movement—delivering full 3D load placement capability.

2. How a Hoist Lift Works — Mechanism and Safety Features

Basic Working Process

A hoist lift operates by motor or manual input turning a drum or sprocket so that the wire rope or chain winds or unwinds, causing the load to rise or descend. Typical steps include:

- Power the motor or pull the hand chain.

- The drum turns, drawing in or paying out cable/chain.

- The load moves up or down.

- The brake system locks to secure the load when operations stop.

Common Drive Types

| Type | Power Source | Advantages | Typical Use |

|---|---|---|---|

| Manual Hoist | Human force | Simple, low maintenance | Light-duty tasks, no-electric environments |

| Electric Hoist | Electric motor | High efficiency, convenient operation | Factories, warehouses |

| Pneumatic Hoist | Compressed air | Intrinsically safer for explosive atmospheres | Chemical, oil & gas |

| Hydraulic Hoist | Hydraulic system | Handles very heavy loads | Shipyards, heavy industry |

Safety Controls

Modern hoist lifts commonly include:

- Overload protection — prevents operation beyond rated capacity;

- Limit switches — stop the hoist at pre-set top/bottom positions;

- Thermal protection — prevents motor overheating;

- Emergency stop — immediately cuts power in urgent situations.

3. Major Types of Hoist Lifts and Their Use Cases

Different hoist types differ in drive method, capacity, and duty. Below is a practical comparison to help you choose:

| Type | Drive | Capacity Range | Typical Industry | Maintenance |

|---|---|---|---|---|

| Manual Chain Hoist | Manual | ≤ 2 tons | Small repairs, construction jobs | Low |

| Electric Wire Rope Hoist | Electric | 1–20 tons | Factories, production lines | Medium |

| Pneumatic Hoist | Compressed air | 0.5–10 tons | Hazardous or explosive environments | Medium |

| Hydraulic Hoist | Hydraulic | 10–100 tons | Heavy construction, shipyards | High |

Selection notes:

- Manual hoists suit intermittent use or sites without power.

- Electric hoists balance speed and cost and are the mainstream for industrial use.

- Pneumatic hoists are chosen for explosion-prone areas.

- Hydraulic hoists are best for ultra-heavy continuous operations.

4. Industrial Applications of Hoist Lifts

Hoist Lift is widely applied across industries:

- Manufacturing: handling molds, machine parts, and tooling;

- Construction: lifting steel beams, precast concrete panels, formwork;

- Warehousing & Logistics: pallet stacking, container loading/unloading;

- Energy & Mining: lifting generator components and heavy mining gear;

- Automotive & Aerospace: precision lifting for assembly tasks.

In most cases, hoists are integrated within a Crane Hoist System to combine vertical lifting with horizontal crane movement—greatly improving productivity and placement accuracy.

5. How to Choose the Right Hoist Lift — Selection Guide

Key parameters when selecting a hoist lift:

| Parameter | Description | Recommendation |

|---|---|---|

| Load Capacity | Rated lifting capacity | Choose ≥ 1.25 × maximum working load |

| Lifting Height | Maximum hoist travel | Determine from building height and layout |

| Working Frequency | Duty cycle | High-frequency tasks favor electric, robust models |

| Environment | Conditions (corrosive, explosive, outdoor) | Use galvanized/stainless or pneumatic models as appropriate |

| Power Supply | Available voltage & phases | Confirm on-site electrical capacity |

Professional tips:

- Verify if the supplier provides CAD drawings and engineering support.

- Prefer drives with VFD (variable frequency drive) and robust braking systems.

- For high-frequency operations, prioritize gearbox and wire rope quality.

If you provide site photos or a short video, we can offer a tailored lifting solution and precise CAD drawings—ensuring correct selection and installation.

6. Common Problems and Maintenance Solutions

Even well-built hoists require routine maintenance. Below are typical issues and practical fixes:

| Problem | Possible Cause | Solution |

|---|---|---|

| Unstable lifting | Worn or loose wire rope | Replace or re-tension the wire rope cable |

| Excessive noise or vibration | Lack of lubrication or misalignment | Lubricate, realign gearbox and bearings |

| Chain slipping | Overload or worn chain | Check load limits; replace chain if necessary |

| Motor overheating | Continuous heavy duty; poor ventilation | Allow cooldown; inspect cooling fan and duty rating |

Maintenance recommendations:

- Inspect brakes and lubrication monthly.

- Check motor and wire rope wear quarterly.

- Use genuine replacement parts to ensure lifespan and safety.

Proper preventive maintenance can substantially reduce downtime and extend service life.

Conclusion

A reliable Hoist Lift delivers not only efficiency but also operational safety and corporate reputation. Selecting quality equipment and a trustworthy manufacturer is essential for project success.

Yonghao Crane brings years of industry experience, dual manufacturing bases, and over 20 technical patents to deliver complete Crane Hoist System solutions—from on-site assessment and CAD design to manufacturing and global installation—ensuring every lift is precise, safe, and dependable.

If you need a durable, accurate hoist lift solution tailored to your site, contact yonghaoqizhong@163.com for expert engineering support and customized lifting systems.